Cold Rolled Steel Strip Technical Specifications

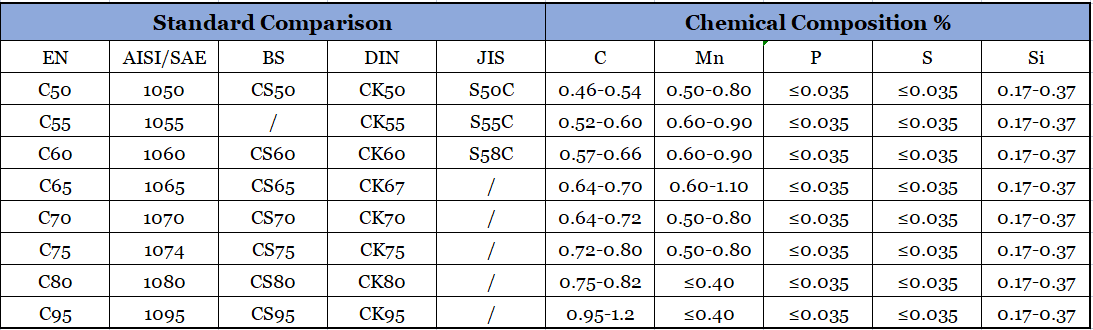

AISI 1050 Annealed Steel

-Our AISI 1050 annealed spring steel is the most cost-effective option.

AISI 1074/1075 Annealed Steel

-Our AISI 1074/1075 Annealed Steel is a medium carbon content metal that boast a stronger and yet flexible composition, ideal for products that require significant strength and flexibility.

AISI 1095 Annealed Steel

-AISI 1095 offers the best quality of all of our annealed spring steels and features the highest carbon content.

Application in Automobile Industry. Widely used for making springs, washers, spacers, clips, pin, inserts and other products.

Technical features:

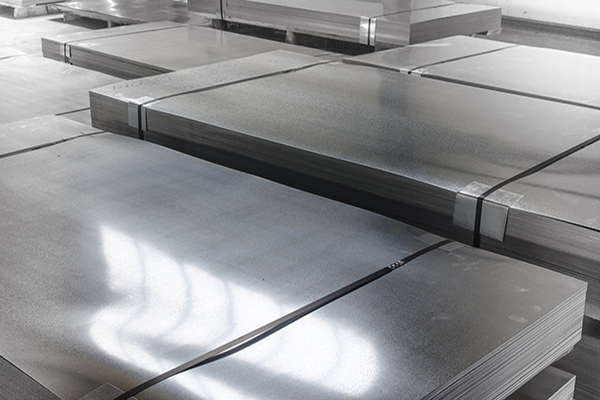

- Thickness from 0,10 mm up to 5,00 mm.

- Width from 5 mm to 1300 mm.

- Bright annealed, smooth surface

- Hardness max 200 HV

- Different finishing surfaces and different special profiles are available

- We serve slitted coils either annealed or hardened & tempered strip, if required edge rounding and cut to length service are available for small or large quantities to meets your demands.